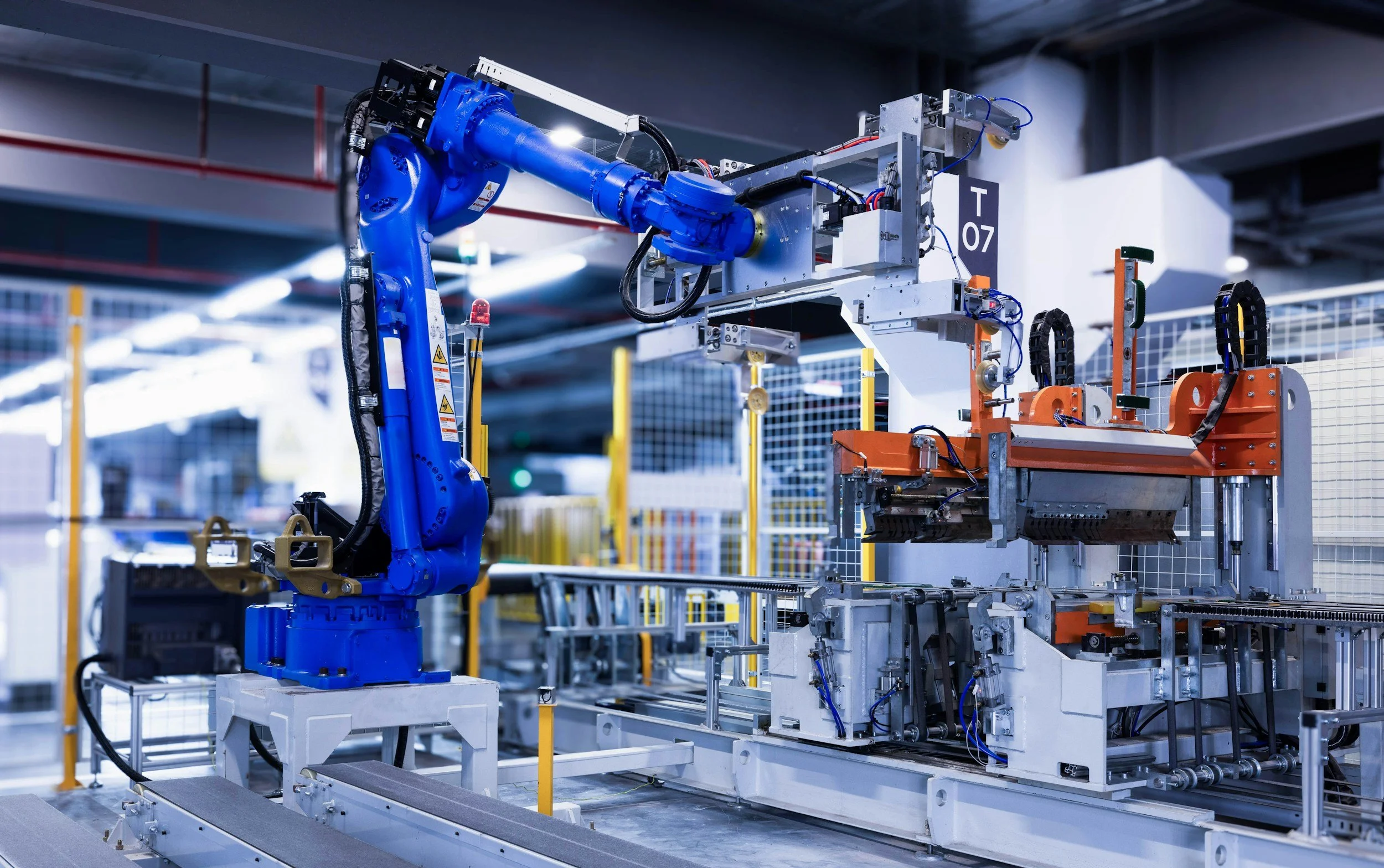

Power Platform Solutions for Manufacturing in Australia

Inturing delivers Microsoft Power Platform consulting, implementation, and optimisation services for manufacturing organisations across Australia.

We help manufacturers digitise operational workflows, automate processes, unify production reporting, and build secure, scalable foundations for AI-enabled decision-making.

We specialise in delivering end-to-end Power Platform solutions from shop-floor Power Apps and approval workflows, to production dashboards, supplier portals, and governance-led platform rollouts that scale across sites, teams and business units.

Why Inturing for Manufacturing?

Most manufacturers do not need cool tech. They need real outcomes.

At Inturing, we focus on building production-ready Power Platform solutions that are:

Fast to roll out

Easy for teams to actually use

Built to scale across sites and shifts

Secure and governed from day one

Set up for AI and Copilot-ready workflows

We do not just build apps or dashboards and disappear. We help you build a platform you can keep improving over time.

Manufacturing Outcomes:

Digitise quality, safety and production checks with evidence capture and audit-ready trails

Automate shopfloor workflows like NCRs, corrective actions, approvals and escalations

Streamline maintenance processes with automated work orders, dispatch and PM scheduling

Reduce downtime by tracking breakdowns, root causes and actions in real time

Create live OEE, output and performance reporting across lines and sites

Build governed data foundations for AI, Copilot and smart factory use cases

-

We automate the stuff that slows operations down. Approvals, escalations, notifications, and handoffs. This means your team spends less time chasing and more time producing.

Common workflows we automate:

purchase approvals and CAPEX

quality deviation and escalation workflows

maintenance notifications and routing

stock exception alerts

reporting distribution and operational reminders

-

We build apps for the shop floor that make it easy to capture information in the moment. Cleanly, consistently, and with the right audit trail.

Typical manufacturing apps include:

QA inspections and checklists

downtime and incident tracking

maintenance request and work order apps

shift handovers and daily logs

safety and compliance reporting

We can include barcode scanning, photo capture, digital signatures, and offline-friendly patterns where needed.

-

We build dashboards that supervisors and leadership can actually use.

That usually includes:

throughput, downtime and OEE reporting

scrap and defect tracking

shift performance dashboards

quality and compliance reporting

executive reporting across sites

The goal is simple. One version of the truth and reporting that drives action.

-

We build secure portals so external stakeholders can self-serve instead of emailing your team all day.

Examples:

supplier onboarding and compliance docs

expiry tracking and renewals

contractor access and onboarding workflows

customer or job status requests, where applicable

-

Power Platform works best when it is connected to your real systems.

We integrate with:

Microsoft 365 (Teams, SharePoint, Outlook)

Dynamics 365

ERP platforms like SAP, Oracle, Pronto, MYOB Advanced

SQL databases and data warehouses

on-prem and legacy systems via gateway

custom APIs and line-of-business systems

You do not need to replace your systems. Power Platform connects them and makes the workflows around them far more efficient.

-

This is what stops Power Platform from turning into a mess over time.

We build governance into the implementation so you can scale safely:

environment strategy and access control

data loss prevention (DLP) policies

auditing and monitoring

lifecycle management and deployment standards

platform documentation and handover

-

Manufacturing workflows need traceability. Not just "we think it happened".

We build solutions that capture:

inspection evidence (photos, signatures, timestamps)

approvals and escalation trails

structured logs for audits and compliance

clear reporting for root-cause analysis

-

AI works best when your processes and data are structured.

We help you get Copilot-ready by:

standardising workflows and data capture

setting up governed data models and permissions

building automation and reporting foundations that AI can actually use

removing the messy data problem before you layer AI on top

-

If you have multiple sites or teams, we build with scale in mind:

reusable components and templates

deployment patterns and release processes

centralised reporting models

platform governance that works long-term

-

Manufacturers do not want a one-off build. They want a platform that improves over time.

We can support:

enhancements and iterations

performance optimisation

reporting expansion

new workflow rollouts

managed services support

Connect the Power Platform to Your Exisiting Manufacturing Systems:

How We Work With You

Manufacturing Power Platform FAQs

Need help with Power Platform in manufacturing? Talk to Inturing about designing, building, and scaling Power Platform solutions across your operations.

-

Microsoft Power Platform is a low-code platform that allows manufacturers to build apps, automate workflows, and create dashboards and portals using Microsoft technology.

At Inturing, we use Power Platform to help manufacturing organisations digitise operations, improve visibility, and standardise processes across sites and teams. -

Power Platform can improve inspection workflows, maintenance requests, approvals, downtime tracking, incident reporting, production reporting, inventory alerts, and supplier onboarding.

We commonly implement solutions that reduce manual admin, improve traceability, and provide real-time operational insights. -

Yes. Power Apps can be used on mobile devices and tablets to support shop-floor workflows such as inspections, handovers, downtime logging and maintenance reporting.

Inturing designs frontline apps that are fast to use, easy to adopt, and structured for clean data capture. -

Power Apps can be used to build QA inspection apps, maintenance request apps, safety reporting apps, shift handover apps, training and competency apps, and operational checklists.

We build apps that support barcode scanning, photo evidence, digital signatures, and structured workflows tailored to your environment. -

Yes. Power Automate is ideal for approvals, escalations, notifications, and workflow routing across manufacturing teams.

Inturing uses Power Automate to automate CAPEX approvals, purchase request workflows, quality deviations, maintenance escalations, and reporting distribution. -

Yes. Power BI can support real-time and near real-time dashboards depending on your data sources and integration approach.

We build production dashboards for throughput, downtime, scrap, quality trends and OEE that help supervisors and leadership act faster. -

Yes. Power Platform can integrate with ERP and manufacturing systems using connectors, gateways, APIs and database integration.

Inturing designs integration patterns based on your system architecture, security requirements, and performance needs. -

Yes. Power Platform integrates natively with Microsoft 365, including Teams, Outlook, SharePoint, and Excel.

We often embed apps in Teams, automate workflows through Outlook, and use SharePoint for structured document and data management. -

Yes. Power Platform includes enterprise-grade security features such as role-based access, environment separation, auditing, and data loss prevention policies.

Inturing implements governance and security controls to ensure solutions remain secure, scalable, and compliant. -

We implement governance frameworks that cover environments, access, security, data connectors, lifecycle management, and standards for building solutions.

This prevents uncontrolled growth and ensures your Power Platform deployment stays maintainable across teams and sites. -

Yes. Power Platform solutions can capture timestamps, approvals, inspection evidence, and structured records to support audits and compliance reporting.

We design workflows that improve traceability for QA inspections, safety reporting, corrective actions, and supplier documentation. -

Yes. Power Platform can scale across multiple sites, business units, and teams while maintaining consistent processes and reporting.

We build solutions with reusable components, central reporting models, and governance strategies designed for long-term scale. -

Yes. Power Pages and Power Apps can be used to build supplier onboarding workflows and portals that collect documentation and track expiry dates.

We implement workflows that reduce back-and-forth communication and improve supplier compliance visibility. -

Yes. Shift handover apps are one of the most effective quick win use cases for manufacturers.

We build solutions that standardise handover notes, track recurring issues, and feed reporting that supports continuous improvement. -

Yes. Maintenance workflows can be digitised using Power Apps and Power Automate to improve triage, escalation, and tracking.

We build maintenance request systems that provide visibility into response times, priority levels, and workload trends. -

Yes. AI works best when your workflows and data are structured and governed.

Inturing helps manufacturers become Copilot-ready by standardising processes, improving data quality, implementing secure access controls, and building AI-ready reporting foundations. -

Timelines vary depending on complexity, integrations, and governance requirements. Many manufacturers start with a quick win project and expand from there.

We typically deliver solutions iteratively, starting with high-impact workflows and then scaling into a roadmap. -

Yes. We provide training for operators, supervisors, admins and internal champions, along with documentation and handover.

We also offer ongoing support and managed services to keep solutions running smoothly and evolving with your business needs. -

Inturing provides Power Platform consulting, architecture, development, governance, and ongoing support for manufacturing organisations across Australia.

We focus on delivering secure, scalable, production-ready solutions that drive real operational outcomes, not just prototypes.